Precision aluminum casting innovations for durable production

Wiki Article

Discover Comprehensive Foundry Services for All Your Metal Casting Requirements

The landscape of metal casting has advanced markedly, with comprehensive foundry services emerging as a vital resource for makers. These services encompass a variety of processes, from pattern making to finishing techniques. By checking out the various offerings and modern technologies readily available, one can better recognize how these remedies enhance efficiency and top quality. The ramifications of picking the right provider, nevertheless, are significant and merit further expedition.Understanding Metal Casting Processes

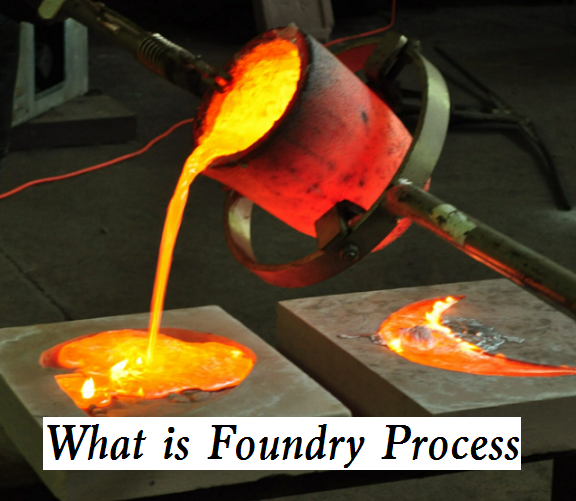

Metal casting is a basic procedure in manufacturing, where liquified metal is poured right into a mold to create preferred shapes and structures. This strategy has actually been made use of for centuries, enabling the production of complicated components across various markets. The procedure starts with the prep work of a mold, which can be made from materials such as sand, metal, or porcelains, relying on the preferred finish and application. As soon as the mold and mildew is ready, metal is heated up to its melting point and afterwards thoroughly put in, guaranteeing that it fills up all cavities. After cooling, the solidified metal takes the shape of the mold. The casting is after that removed and usually needs ending up procedures, such as machining or polishing, to accomplish specific measurements and surface high quality. Comprehending these essential procedures is important for any person included in the manufacturing and engineering sectors, as it prepares for efficient design and production.Sorts Of Foundry Services Supplied

Foundries supply a varied series of services tailored to fulfill the particular requirements of numerous industries. Amongst these services, pattern making sticks out as a crucial step, where molds are produced from products like wood or metal to form the end product. Additionally, metal pouring is a basic service, including the transfer of liquified metal into the prepared molds.Foundries likewise use completing services, which incorporate procedures such as machining, brightening, and surface therapy to improve the last appearance and capability of actors elements. Quality assurance is an additional essential service, ensuring that the castings satisfy industry criteria and specifications.

Several foundries offer design support, assisting clients in style optimization and material choice. This extensive technique allows shops to satisfy fields such as auto, aerospace, and building, making certain that they fulfill the differing demands of their customers successfully.

Benefits of Using Extensive Foundry Services

Utilizing comprehensive foundry services provides many benefits that considerably boost production effectiveness and quality. By providing a one-stop option for various metal casting needs, these services enhance the manufacturing procedure, lowering preparations and reducing the need for multiple suppliers. This integrated technique promotes far better communication and sychronisation, permitting a lot more specific control over production timelines.In addition, detailed foundry services typically assure exceptional quality with standard procedures and professional oversight. This uniformity assists in conference stringent industry guidelines and client specs. Furthermore, the accessibility to a varied variety of materials and casting methods enables companies to select the most effective solutions for their particular tasks.

Cost-effectiveness is an additional significant benefit, as packed services can result in economic situations of range. Ultimately, using extensive foundry services not just improves functional effectiveness yet additionally advertises advancement and adaptability in item growth, making it a calculated choice for services in the metal casting sector.

Advanced Technologies in Metal Casting

As the metal casting sector progresses, the integration of innovative modern technologies plays an important duty in boosting production abilities and top quality. Advancements such as computer-aided style (CAD) and computer-aided manufacturing (CAM) have changed linked here conventional techniques, permitting for a lot more reliable and specific styles. Additive manufacturing, frequently known as 3D printing, is transforming the prototyping process, making it possible for rapid manufacturing of intricate geometries that were previously difficult to attain.Furthermore, automation and robotics simplify recurring tasks, lowering labor costs and decreasing human error. The fostering of simulation software application makes it possible for shops to anticipate end results and maximize procedures, inevitably causing decreased waste and boosted source administration. Advancements in materials scientific research contribute to the growth of new alloys and compounds that enhance performance and resilience. Jointly, these technologies are not just enhancing functional performances however additionally placing the metal casting sector for future development and innovation.

Just how to Select the Right Foundry Service Carrier

Exactly how can one this page figure out one of the most suitable foundry provider for their certain requirements? It is necessary to analyze the supplier's know-how and experience in the pertinent metal casting procedures. This consists of assessing their abilities in dealing with different materials and their familiarity with market criteria.Next, possible customers ought to take into consideration the provider's technological capabilities. A shop that uses sophisticated technologies can typically deliver greater accuracy and effectiveness. Furthermore, examining the provider's quality control procedures is essential; strong top quality control procedures show a commitment to creating reliable products.

In addition, examining past customer reviews and case studies can supply understandings right into the service provider's performance and client satisfaction. Effective communication and cooperation are necessary; a receptive and transparent company will facilitate a smoother project. By methodically examining these aspects, one can make a notified choice in picking the ideal foundry company.

Regularly Asked Questions

What Products Can Be Made Use Of for Various Metal Casting Procedures?

Numerous products can be utilized in metal casting processes, including aluminum, steel, bronze, magnesium, and iron - Precision aluminum casting. Each material has special residential or commercial properties, making it appropriate for particular applications within the diverse array of casting methods readily availableFor how long Does the Metal Casting Process Commonly Take?

The metal casting procedure usually takes numerous weeks, relying on variables such as manufacturing, material, and complexity volume. First design and mold development can substantially influence the general timeline prior to final casting and completing.Are There Minimum Order Quantities for Foundry Services?

Many shops impose minimal order quantities to assure cost-effectiveness and performance in manufacturing. These amounts can differ based upon the sort of metal, complexity of the casting, and specific solution agreements with clients.Can Personalized Layouts Be Accommodated in Metal Casting?

Yes, personalized designs can be accommodated in metal casting. Foundries usually provide flexibility to develop special patterns and mold Continue and mildews, ensuring that specific customer demands are satisfied while keeping high standards of top quality and precision.What Certifications Should a Shop Company Have?

A reliable foundry company ought to have certifications such as ISO 9001 for quality monitoring, ISO 14001 for environmental administration, and certain industry accreditations associated to safety and security and conformity, making sure adherence to finest practices and standards.The landscape of metal casting has developed significantly, with considerable foundry services arising as an essential resource for manufacturers. Metal casting is an essential process in manufacturing, where liquified metal is put into a mold to develop preferred shapes and frameworks. Among these services, pattern making stands out as a crucial action, where molds are produced from products like timber or metal to shape the last item. By supplying a one-stop option for various metal casting needs, these services improve the production procedure, minimizing lead times and decreasing the need for numerous suppliers - Aluminum Casting Company. It is important to examine the service provider's know-how and experience in the appropriate metal casting procedures

Report this wiki page